Managing waste liquid efficiently and safely is crucial in both industrial and environmental sectors. Waste liquid absorbents play a key role in this process, ensuring that harmful substances are effectively contained and treated. This guide explores various aspects of waste liquid absorbents, from their materials to their applications.

Understanding Waste Liquid Absorbents

Waste liquid absorbents are specialized materials designed to absorb and retain liquid waste, simplifying disposal and making it more environmentally friendly. These absorbents can handle a wide range of liquids, including both hazardous chemicals and non-hazardous substances.

Types of Liquid Absorbents

There are several types of liquid absorbents, each suited to different applications. Common types include:

- Chemical absorbents: Ideal for handling hazardous chemical spills.

- Environmental absorbents: Designed for eco-friendly waste management.

- Industrial absorbents: Used in industrial settings to manage large volumes of waste liquid.

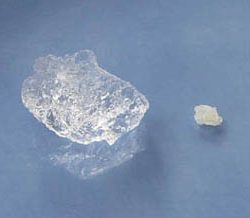

Absorbent Materials

Absorbent materials vary widely, with each type tailored to specific needs. Common materials include:

- Natural fibers

- Synthetic polymers

- Mineral-based products

These materials are selected for their high absorption capacity and efficiency.

Absorbent Products and Their Applications

A variety of absorbent products are available on the market, including mats, pads, booms, and pillows. These products are used in diverse settings such as:

- Industrial waste liquid treatment

- Environmental spill response

- Everyday waste management tasks

The Role of Absorbent Technology

Advances in absorbent technology have led to the development of more efficient and effective products. Innovations focus on increasing absorbent capacity and efficiency, ensuring that spills are managed quickly and effectively.

Absorbent Manufacturing and Selection

The manufacturing of absorbents involves careful selection of materials and processes to create products that meet specific needs. When selecting absorbents, consider factors such as:

- Absorbent performance: How quickly and effectively the absorbent can contain the liquid.

- Absorbent safety: Ensuring the absorbent material does not react adversely with the liquid.

- Absorbent composition: The materials used and their environmental impact.

The Absorbent Market

The absorbent market is expanding, driven by the increased demand for efficient waste liquid management solutions. This growth is fueled by stricter environmental standards for absorbents and a greater awareness of environmental protection.

Pricing and Suppliers

Absorbent pricing varies based on type, material, and capacity. Researching absorbent suppliers is essential to find products that meet both performance requirements and budget constraints.

Absorbent Research

Ongoing research in absorbent technology aims to improve materials and products, focusing on developing more sustainable, efficient, and cost-effective solutions for waste liquid management.

Conclusion

Effective waste liquid treatment is essential for maintaining a safe and clean environment. By understanding the different types of absorbents, their applications, and the latest technologies, industries can make informed choices about the products they use. Investing in high-quality absorbents ensures compliance with environmental standards and enhances overall operational efficiency.

Whether managing industrial spills or everyday waste, selecting the right absorbent is key to successful waste management.